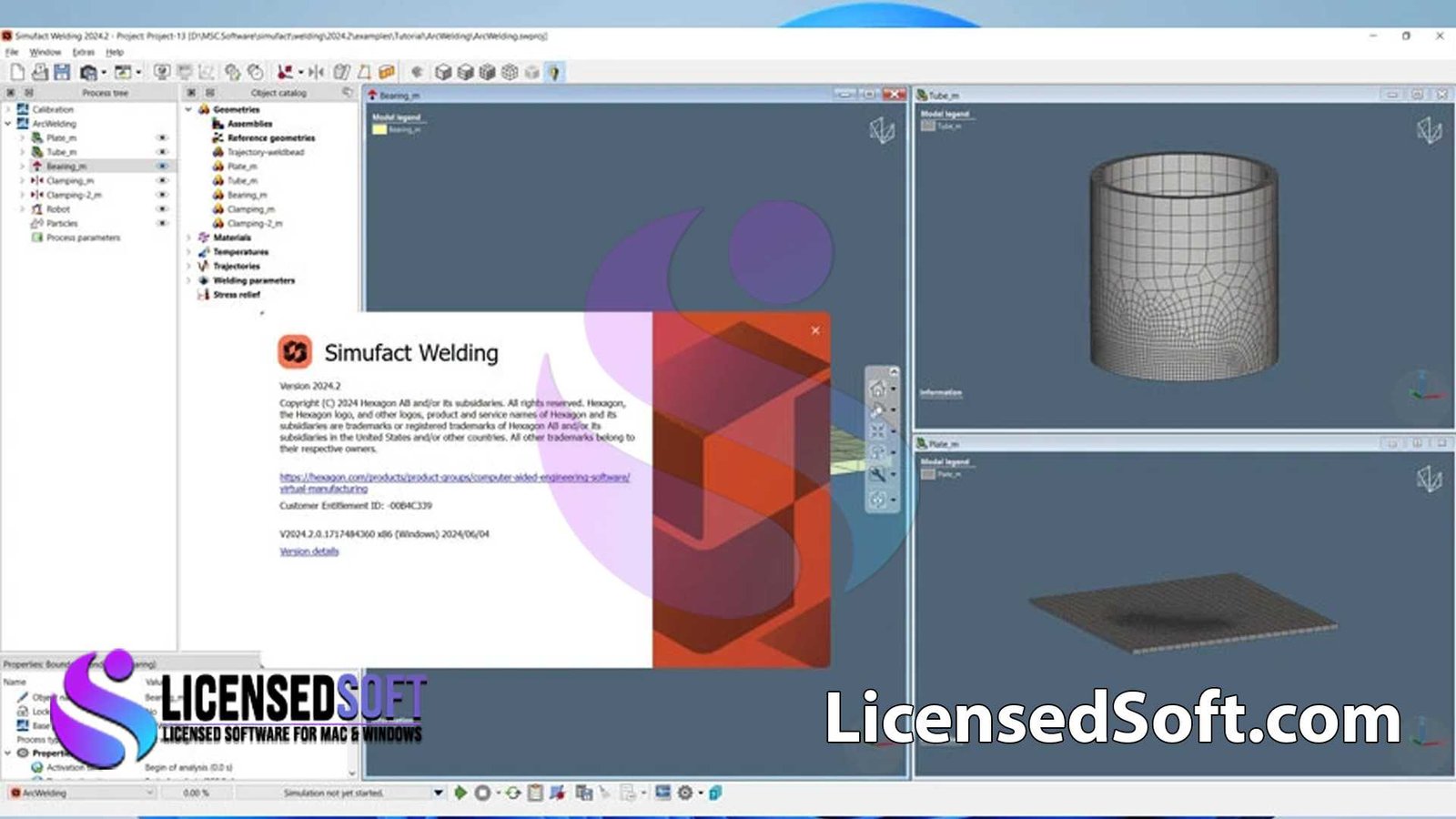

MSC Simufact Welding 2024.2 Full Version. Simufact Welding 2024.2 is MSC’s advanced simulation software tailored to model and optimize welding and additive manufacturing processes. Including arc welding, laser welding, resistance seam welding, and hybrid methods. It enables engineers to predict distortion, residual stresses, structural integrity, and metallurgical transformations during manufacturing. You can also get Hexagon PC-DMIS 2023.2 Full Version from LicensedSoft.

MSC Simufact Welding 2024.2 Key Features:

- Multi-Process Welding Support – Model various processes, including GMAW/MIG, GTAW/TIG, laser, ultrasonic, friction stir, resistance, hybrid, and AM welding with consistent interfaces.

- 3D Thermal-Mechanical Simulation – Accurately couple heat transfer, phase transformation, mechanical loading, and stress evolution in welded joints and additively built structures.

- Residual Stress & Distortion Analysis – Quantify distortions and residual stresses, simulate structural deformations, and optimize fixture designs and welding sequences.

- Microstructure Prediction – Integrate metallurgical models to assess grain structure, hardness variation, and hardness for weld and heat-affected zones (HAZ).

- Automation & User-Friendly Interface – Guided setup wizards, parameter templates, and API scripting for batch processing and customized production workflows.

- Fixture & Weld Sequencing Optimization – Automate sequencing and clamping strategies in shoemake weld setups to minimize deformation and improve weld quality.

- CAD and FEA Integration – Compatible with major CAD formats and FEA tools (e.g., MSC Nastran, Abaqus, ANSYS) for complete CAD-to-analysis workflows.

- Post-Processing & Visualization – Easily visualize results with contour plots, animations, and exportable data for reporting or downstream FEA input.

MSC Simufact Welding 2024.2 System Requirements:

- Operating System: Windows 10/11 64-bit or Linux (RHEL/CentOS)

- Processor: Multi-core Intel Xeon or AMD EPYC

- RAM: 16 GB minimum (32 GB+ recommended)

- Storage: ≥10 GB free for installation and temporary simulation data

- Graphics: OpenGL-compatible GPU for viewport rendering

- Additional: MSC FlexNet license server required; proper heat exchanger licensing for welding modules

MSC Simufact Welding 2024.2 Licensing & Support:

- License Type: Perpetual or monthly-floating via MSC FlexNet; modules sold separately.

- Support: Includes technical support, updates, training, and access to simulation best practices through MSC channels.

Ideal For

- Welding Engineers & Fabricators predicting distortion and planning weld parameters.

- Structural Engineers analyzing as-built weld quality, stress integrity, and performance.

- Metal Additive Manufacturing Specialists optimizing build strategies, residual stress, and thermal history.

- Process R&D Teams comparing process methods and designing control strategies.

- Fixture Designers reducing trial-and-error by optimizing clamp and tack sequences.

Conclusion

Hexagon Simufact Welding 2024.2 provides an integrated, robust solution for simulating welding and additive processes, accurately predicting thermal, mechanical, and metallurgical outcomes. It helps engineers reduce risk, minimize iterations, optimize performance, and deliver high-quality welded products and parts. Want to explore case studies or compare it to other welding simulation tools?