Siemens Tecnomatix Plant Simulation 2302 Optimizing Manufacturing Operations. Siemens Tecnomatix Plant Simulation 2302, equipped with its premium perpetual license, emerges as a pivotal solution for industries seeking to optimize manufacturing operations. This comprehensive overview delves into the key features, functionalities, and applications that make Tecnomatix Plant Simulation an indispensable tool for improving efficiency, reducing costs, and enhancing overall productivity in diverse manufacturing environments.

Introduction to Siemens Tecnomatix Plant Simulation 2302

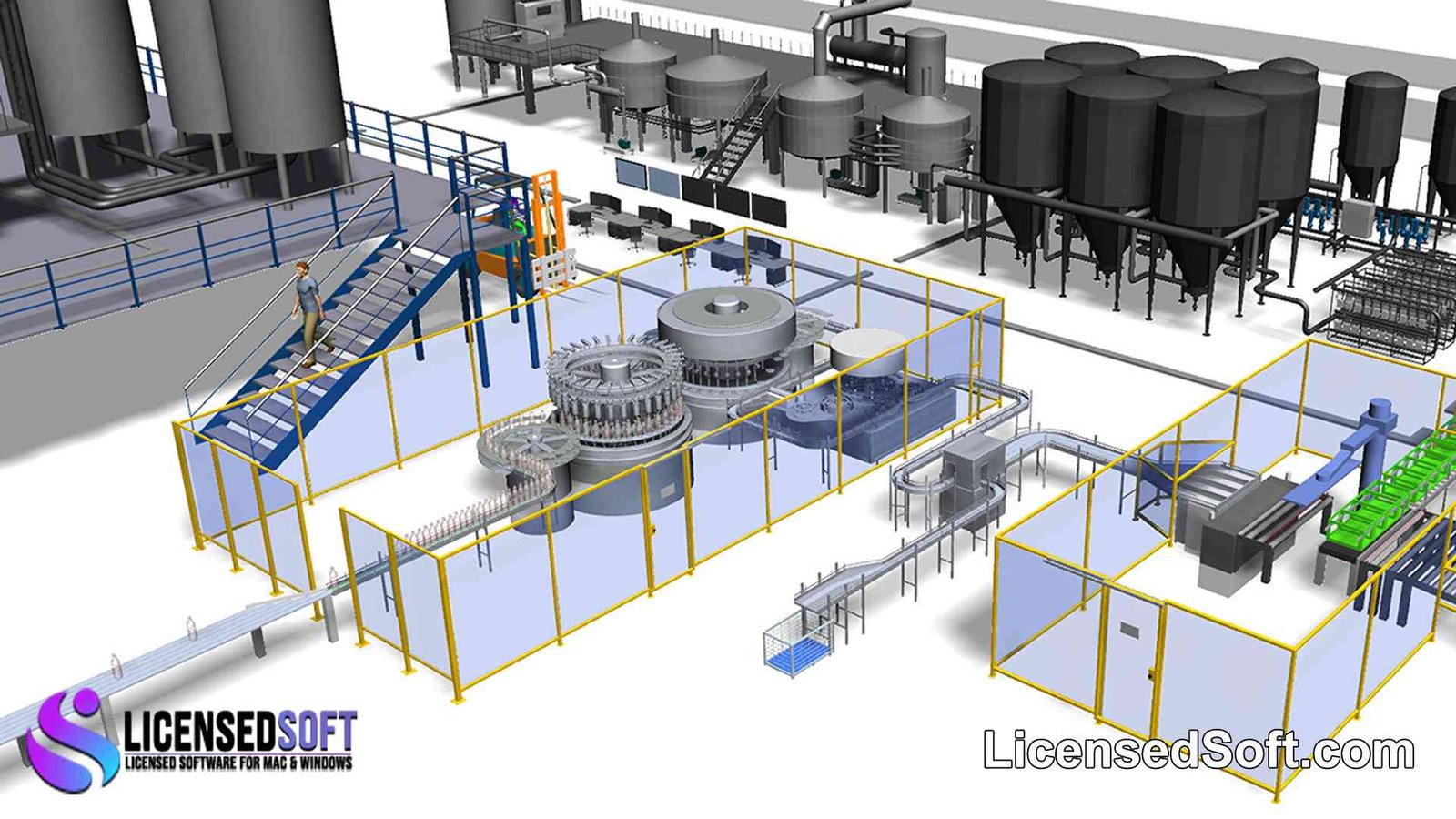

Siemens Tecnomatix Plant Simulation is a powerful software solution designed to model, simulate, and analyze manufacturing processes and systems. Version 2302, with its premium perpetual license, introduces advanced capabilities to help companies visualize, optimize, and make informed decisions regarding their production operations.

Key Features of Siemens Tecnomatix Plant Simulation 2302

1. Dynamic Simulation Modeling:

- Tecnomatix Plant Simulation allows users to create dynamic simulation models of manufacturing systems. These models provide a virtual representation of the entire production process, enabling users to analyze system behavior under different conditions.

2. Material Flow Analysis:

- The software excels in material flow analysis, allowing users to simulate the movement of materials within a manufacturing facility. This includes the optimization of conveyor systems, storage areas, and material handling processes.

3. Resource Allocation and Optimization:

- Users can optimize the allocation of resources, including machines, robots, and personnel, to maximize efficiency. Tecnomatix Plant Simulation helps in identifying bottlenecks, minimizing idle time, and improving overall equipment effectiveness (OEE).

4. Energy Consumption Analysis:

- The software includes tools for analyzing energy consumption within the manufacturing environment. This is crucial for industries aiming to reduce energy costs and improve sustainability by identifying opportunities for efficiency enhancements.

5. Robotic and Automation Simulation:

- Tecnomatix Plant Simulation supports the simulation of robotic and automation systems. Users can model and analyze the interactions between robots, automated guided vehicles (AGVs), and other elements in the production line. You can also get Siemens Tecnomatix Process Simulate 2307 Premium By LicensedSoft.

6. Advanced Visualization:

- The software offers advanced visualization capabilities, allowing users to create 3D models of manufacturing facilities. This aids in the visualization of complex layouts and facilitates a better understanding of the production environment.

7. Statistical Analysis and Optimization:

- Tecnomatix Plant Simulation includes statistical analysis tools to evaluate system performance. Users can run simulations under different scenarios and use optimization algorithms to find the most efficient configuration for manufacturing operations.

8. Scenario Analysis and What-If Simulations:

- Users can perform scenario analysis and conduct what-if simulations to assess the impact of changes in the manufacturing process. This helps in making informed decisions regarding process improvements and system modifications.

9. Integration with PLM and MES Systems:

- The software seamlessly integrates with Product Lifecycle Management (PLM) and Manufacturing Execution Systems (MES), ensuring data consistency and collaboration between design and manufacturing teams.

10. Scalability and Flexibility:

- Tecnomatix Plant Simulation is designed to be scalable and adaptable to varying manufacturing needs. It caters to a wide range of industries, including automotive, pharmaceuticals, discrete manufacturing, and more.

Applications of Siemens Tecnomatix Plant Simulation

Tecnomatix Plant Simulation finds applications across diverse industries:

1. Automotive Manufacturing:

- In the automotive industry, Tecnomatix Plant Simulation is used to optimize assembly lines, production schedules, and logistics. It aids in identifying opportunities for efficiency improvements and cost reductions.

2. Pharmaceutical Production:

- Pharmaceutical manufacturers leverage Tecnomatix Plant Simulation to optimize batch processing, logistics, and material handling. The software ensures compliance with regulatory requirements and enhances overall operational efficiency.

3. Discrete Manufacturing:

- For industries involved in discrete manufacturing, such as electronics and machinery production, TecnomatixPlant Simulation helps in streamlining production processes, reducing lead times, and optimizing resource utilization.

4. Logistics and Warehousing:

- The software is applied in the simulation and optimization of logistics and warehousing operations. Users can design and analyze distribution centers, identify potential bottlenecks, and enhance overall supply chain efficiency.

Advancing Manufacturing Efficiency with Siemens Tecnomatix Plant Simulation

In conclusion, Siemens TecnomatixPlant Simulation 2302 with its premium perpetual license stands as a pivotal solution for industries aiming to optimize manufacturing operations. Its capabilities in dynamic simulation modeling, material flow analysis, resource optimization, and integration with PLM and MES systems contribute to improved efficiency, reduced costs, and enhanced decision-making in manufacturing environments. Whether in automotive, pharmaceuticals, discrete manufacturing, or logistics, TecnomatixPlant Simulation empowers companies to visualize, simulate, and optimize their production processes, ultimately leading to increased competitiveness in the global market. As a key player in the realm of manufacturing efficiency, Siemens TecnomatixPlant Simulation continues to drive advancements, providing the tools needed for smart, connected, and optimized manufacturing systems.