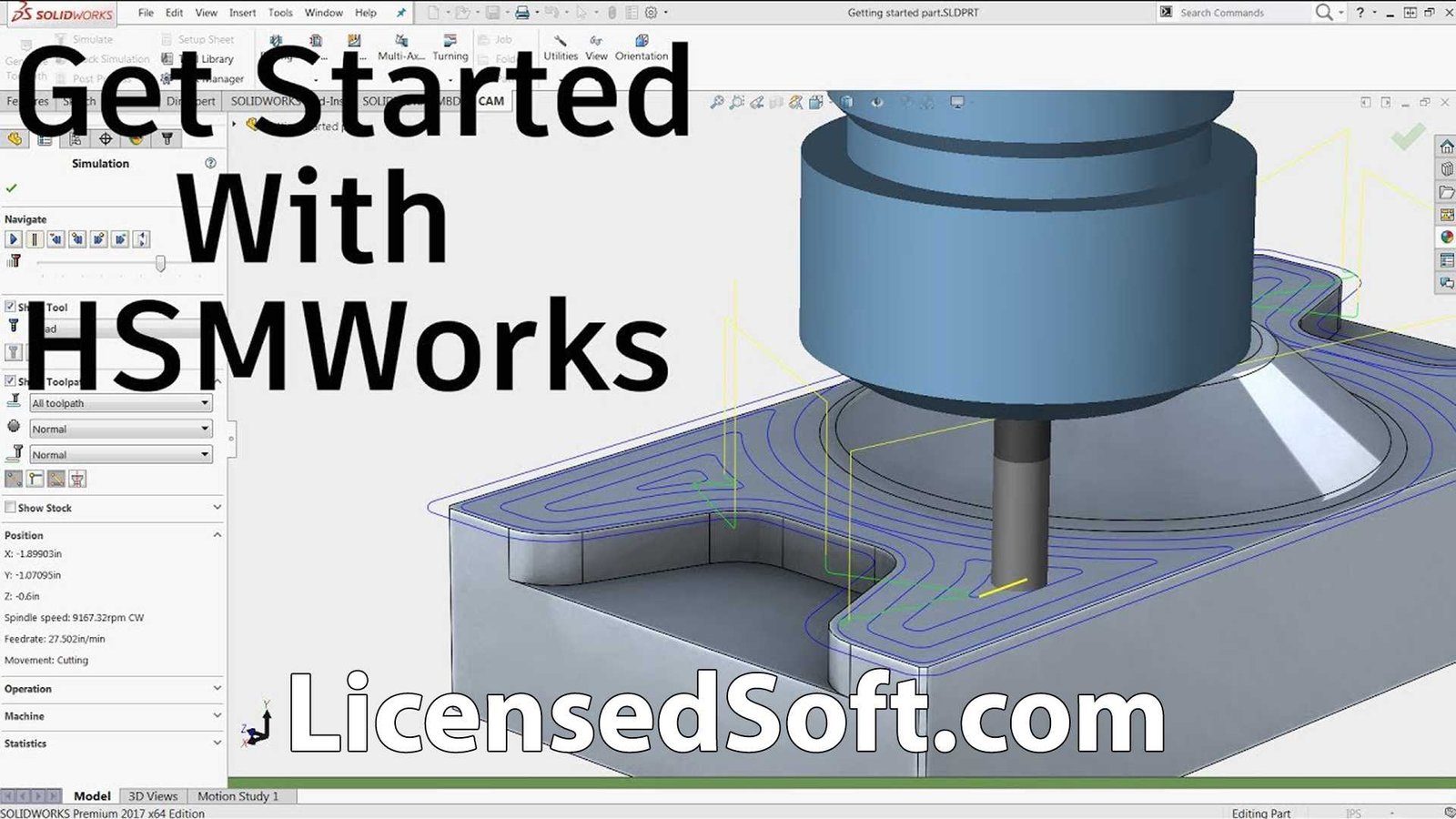

Autodesk HSMWorks Ultimate 2024: Revolutionizing CNC Machining and Manufacturing Efficiency. In the ever-evolving landscape of manufacturing, precision and efficiency are paramount to achieving exceptional results. Enter Autodesk HSMWorks Ultimate 2024, a cutting-edge software solution designed to revolutionize the field of CNC machining and manufacturing. In this comprehensive article, we will explore the key features, benefits, and transformative impact of Autodesk HSMWorks Ultimate 2024 on the world of machining and production.

Introduction to Autodesk HSMWorks Ultimate 2024: Redefining CNC Machining. Autodesk HSMWorks Ultimate 2024 stands as a pinnacle in the field of Computer Numerical Control (CNC) machining. Tailored to address the complexities of machining processes, this software offers a plethora of features that streamline machining workflows, enhance accuracy, and usher in a new era of manufacturing excellence.

Autodesk HSMWorks Ultimate 2024 New Features:

1. Elevating CNC Machining:

At the heart of Autodesk HSMWorks Ultimate 2024 lies its ability to elevate CNC machining through intuitive tools and advanced capabilities. The software empowers machinists, engineers, and manufacturers with a platform that optimizes toolpaths, simulates machining operations, and accelerates the machining process. By providing efficient CAM (Computer-Aided Manufacturing) solutions, HSMWorks Ultimate 2024 ensures precision, reduced cycle times, and enhanced tool life.

2. Seamless Integration and Workflow:

Autodesk HSMWorks Ultimate 2024 excels in fostering seamless integration and workflow optimization. The software seamlessly integrates with various CAD (Computer-Aided Design) software, creating a unified platform for design and manufacturing. This integration eliminates data translation issues, reduces errors, and fosters efficient communication among design and manufacturing teams. You can also get Autodesk MotionBuilder 2024 By LicensedSoft.

3. Advanced Toolpath Strategies:

A pivotal advantage of Autodesk HSMWorks Ultimate 2024 is its integration of advanced toolpath strategies. Machinists can choose from a wide range of machining strategies, including adaptive clearing, 3D contouring, and high-speed machining. These strategies are intelligently designed to optimize material removal rates, reduce tool wear, and achieve high-quality surface finishes.

4. Collision Detection and Simulation:

HSMWorks Ultimate 2024 offers collision detection and simulation tools that enable machinists to visualize and validate machining operations before they are executed on the shop floor. This feature aids in identifying potential collisions, verifying tool clearances, and ensuring the overall accuracy of the machining process.

5. Multi-Axis Machining:

Autodesk HSMWorks Ultimate 2024 empowers manufacturers with multi-axis machining capabilities. The software enables the creation of complex toolpaths for 4- and 5-axis machining, opening doors to intricate part geometries and reducing the need for multiple setups. Multi-axis machining increases productivity and allows for the production of intricate parts with ease.

Benefits of Autodesk HSMWorks Ultimate 2024:

The introduction of Autodesk HSMWorks Ultimate 2024 brings forth a multitude of benefits that resonate within the machining and manufacturing community:

1. Streamlined Machining Workflow:

HSMWorks Ultimate 2024 streamlines the machining process, reducing manual effort and expediting the production timeline.

2. Collaborative Design and Manufacturing:

The software enables real-time collaboration between design and manufacturing teams, fostering efficient communication and coordination.

3. Advanced Toolpath Strategies:

Integration of advanced toolpath strategies optimizes machining efficiency, tool life, and surface finishes.

4. Collision Detection and Simulation:

Collision detection tools enhance machining accuracy by identifying potential collisions and verifying tool clearances.

5. Multi-Axis Machining:

Multi-axis capabilities enable the machining of complex geometries and reduce the need for multiple setups.

6. Transforming Manufacturing Excellence:

Autodesk HSMWorks Ultimate 2024 signifies the ongoing transformation within CNC machining and manufacturing. By optimizing toolpaths, enhancing collaboration, and providing advanced simulation tools, the software empowers machinists and manufacturers to deliver high-quality products with improved production efficiency.

7, Advancing Precision and Efficiency:

As Autodesk HSM Works Ultimate 2024 evolves, manufacturers can anticipate even greater advancements in machining capabilities. The software’s commitment to innovation promises to refine toolpath strategies, collision detection tools, and multi-axis machining features, offering professionals even more sophisticated solutions to navigate the complexities of CNC machining.

In Conclusion:

Autodesk HSM Works Ultimate 2024 and the Future of CNC Machining. Autodesk HSM Works Ultimate 2024 stands as a testament to the convergence of technology and CNC machining. Its streamlined machining workflows, collaborative capabilities, and advanced simulation tools mark a new chapter in manufacturing excellence. Manufacturers now possess the tools to create products that exemplify precision, reduced cycle times, and innovative design.

As CNC machining continues to evolve, Autodesk HSM Works Ultimate 2024 remains a beacon of progress, guiding manufacturers toward a future where machining is not just a process but a transformative approach to manufacturing that pushes the boundaries of precision, efficiency, and operational excellence. It is through such advancements that CNC machining solidifies its role as a pivotal force in shaping industries that demand precision, innovation, and unmatched manufacturing efficiency.