Siemens Simatic WinCC v7.5 Revolutionizing Human-Machine Interface (HMI) Solutions. Siemens Simatic WinCC v7.5, with its premium perpetual license, stands as a cornerstone in the realm of Human-Machine Interface (HMI) solutions. In this comprehensive overview, we will explore the key features and capabilities that make Simatic WinCC v7.5 an indispensable tool for industrial automation and control systems.

Introduction to Simatic WinCC v7.5

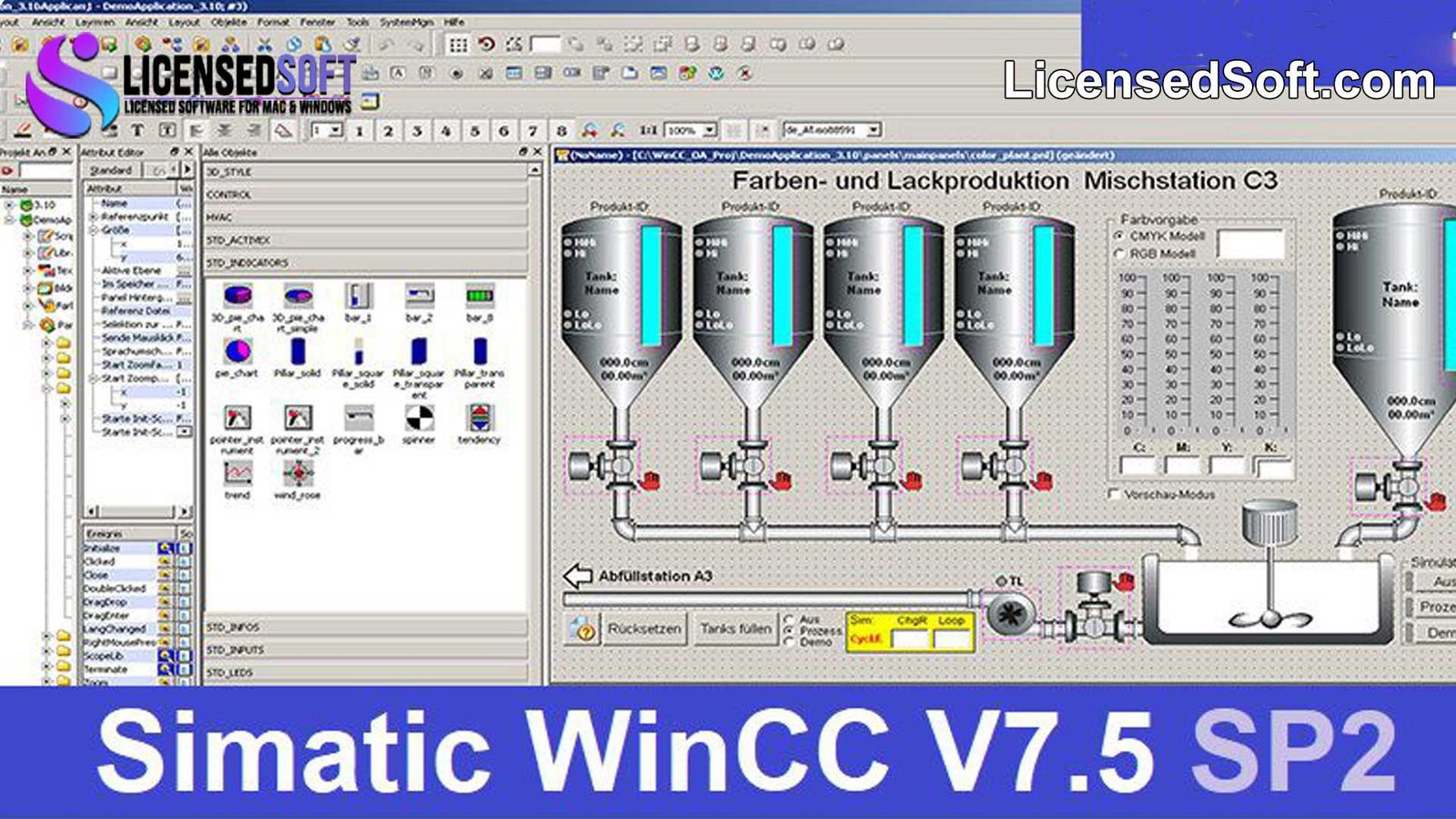

Siemens Simatic WinCC is a powerful software suite designed for the development and operation of Human-Machine Interfaces (HMIs) in industrial automation environments. The v7.5 version represents the latest iteration, offering a range of advanced features to enhance visualization, control, and monitoring of industrial processes.

Key Features of Simatic WinCC v7.5

1. Intuitive HMI Design:

- Simatic WinCC v7.5 provides an intuitive and user-friendly environment for designing HMI screens. Engineers can create visually appealing and easy-to-navigate interfaces that facilitate efficient control and monitoring of industrial processes.

2. Scalable System Architecture:

- The software offers a scalable system architecture, making it suitable for applications of varying sizes and complexities. From small-scale machine-level HMI to large-scale supervisory control systems, Simatic WinCC v7.5 adapts to the specific needs of the industrial environment.

3. Multi-Touch and Multi-Monitor Support:

- With support for multi-touch and multi-monitor configurations, Simatic WinCC v7.5 allows operators to interact with the system in a way that suits their preferences and enhances productivity. This is particularly beneficial in scenarios where multiple displays or touch interactions are required.

4. Advanced Visualization:

- Engineers can create advanced visualizations using a wide range of graphic elements, animations, and dynamic objects. This enhances the representation of industrial processes, making it easier for operators to understand and respond to real-time data.

5. Alarm and Event Handling:

- Simatic WinCC v7.5 includes robust alarm and event handling capabilities. Operators receive timely notifications about critical events or deviations in the industrial process, enabling swift responses to ensure system integrity and productivity.

6. Data Logging and Reporting:

- The software enables comprehensive data logging, allowing users to record and analyze historical process data. Additionally, Simatic WinCC v7.5 supports the generation of reports, facilitating performance analysis, troubleshooting, and regulatory compliance.

7. Integration with PLC Systems:

- Seamless integration with Siemens PLC (Programmable Logic Controller) systems enhances the synergy between control and visualization. Simatic WinCC v7.5 can directly connect to PLCs, enabling real-time data exchange and synchronization.

8. Web-Based Client Applications:

- Simatic WinCC v7.5 supports the development of web-based HMI applications. This feature allows remote monitoring and control of industrial processes through web browsers, providing flexibility and accessibility to operators. You can also get Siemens Simcenter Amesim 2304 Premium Perpetual License By LicensedSoft.

9. Security Features:

- Security is a priority in industrial automation. Simatic WinCC v7.5 incorporates security features such as user authentication, access control, and encrypted communication to safeguard the integrity and confidentiality of industrial data.

10. Global Language Support:

- For multinational corporations and global operations, Simatic WinCC v7.5 offers support for multiple languages. This ensures that the HMI interface can be customized to meet the linguistic preferences of operators in diverse locations.

Simatic WinCC v7.5 for Industrial Automation Excellence

Simatic WinCC v7.5 is widely used in various industries for industrial automation and control:

1. Manufacturing:

- In manufacturing facilities, Simatic WinCC v7.5 plays a crucial role in monitoring and controlling production processes. The intuitive interface and real-time data visualization contribute to operational efficiency.

2. Oil and Gas:

- The software is applied in the oil and gas industry for supervisory control and monitoring of drilling operations, refining processes, and pipeline systems. It ensures the smooth and safe operation of critical infrastructure.

3. Chemical Processing:

- Simatic WinCC v7.5 is utilized in chemical plants for visualizing and managing complex chemical processes. The software’s scalability and advanced visualization capabilities make it suitable for diverse applications.

4. Power Generation:

- Power plants leverage Simatic WinCC v7.5 to monitor and control the generation, distribution, and consumption of electrical power. The software contributes to the reliable and efficient operation of power generation facilities.

5. Water and Wastewater Treatment:

- In water and wastewater treatment plants, Simatic WinCC v7.5 aids in the visualization and control of treatment processes. Its alarm handling and data logging features contribute to the optimization of water treatment operations.

Advancing Industrial Automation with Simatic WinCC v7.5

In conclusion, Siemens Simatic Win CC v7.5, with its premium perpetual license, stands as a pinnacle in the domain of Human-Machine Interface solutions. Its intuitive design tools, scalable architecture, advanced visualization capabilities, and seamless integration with PLC systems contribute to its significance in industrial automation. Whether applied in manufacturing, oil and gas, chemical processing, power generation, or water treatment, Simatic Win CC v7.5 empowers industries to achieve operational excellence through efficient control and monitoring of industrial processes. With a commitment to continuous innovation, Siemens Simatic Win CC v7.5 remains a driving force in advancing indus